ZD60 Gear Measurement Center

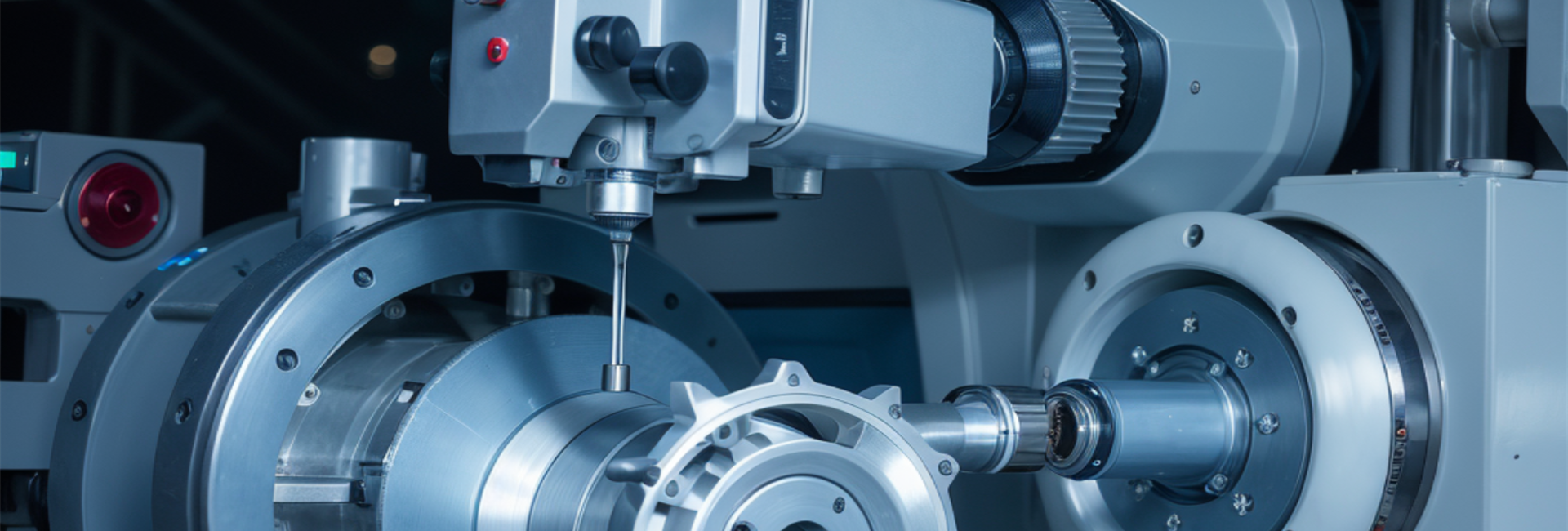

ZD60 series gear measuring center is a novel product series of Harbin Zhida approaching the advanced world level. It adopts 4-axis (X, Y, Z, C) measuring principle, a natural granite base, an integrated layout, a quasi-3D digital scanning probe, a stylus management system based on magnetic adapters, (all-axis) full closed-loop control technologies, hierarchical CNC control techniques, high precision optical encoders, DDR and servo motors, precision roller guides, ball screw transmissions, computerized data acquisition and processing technologies etc. The instrument can automatically and precisely measure profile deviations, helix deviations, pitch deviations, cumulative pitch deviations, runout and other items of involute cylindrical gears (gear clusters, internal gears etc.), gear cutters (hobs, shaping cutters, shaving cutters etc.), worms, worm wheels, spiral (straight) bevel gears etc. Furthermore, it supports extensions such as measuring camshafts, cylindrical workpiece's index and scan tooth contours. ZD series gear measuring center leads the development direction of gear measuring instruments.

View on map

Product Introduction

1. Cylindrical gear

2. Spline (internal and external):

3. Gear cluster

4. Gear cutter

5. Worm gear and worm

6. Rack

7. Spiral bevel gear and straight bevel gear

8. Other cutter

Modulus measured gear ------------------------------------------ 0.3~25 mm

Maximum overall diameter measured gear ------------------------ 650mm

Vertical measurement range ---------------------------------------- 450mm

Distance between the two centers ---------------------------------- 10 ~1000mm

Measurable tooth Angle range -------------------------------------- 0 ~ 90°

The largest workpiece weight --------------------------------------- 500Kg

Power supply voltage ---------------------------------------------- 380V/50Hz

Power supply ------------------------------------------------------- 3.0KVA

1) Stable host system

2) Advanced quasi-3D digital scanning probe system

3) International stylus management system

4) Reliable encoders as positioning references

5) Precise control and data acquisition system

6) Unique hierarchical control techniques

1. Full-automatic measurement

2. High-density uniform sampling

3. User-friendly interfaces

4. Automatic calculation

5. Compensation of eccentricity error in clamping

6. Multiple evaluation systems

7. Multiple report formats

8. Special functions

9. Customization possible